AquiSense

UV-C LED Technology

UV-C LED disinfection is new technology that uses light to damage the DNA of pathogens. This technology offers a variety of new benefits when compared to conventional UV purification. Similar to how visible LEDs effected the display market, AquiSense believes UV-C LEDs will have a lasting effect on how we disinfect water, surfaces and air.

UV-C presents an innovative solution for providing clean and effective water, surface, and air purification.

What is UV-C?

UV (ultraviolet) light is a type of radiation that can be found in the electromagnetic spectrum and is measured in Nanometers (nm). Invisible to the human eye, UV is an effective disinfectant due to the density of its wavelength.

There are four ranges to UV light – UV-A, UV-B, UV-C and Vacuum-UV:

- UV-A – otherwise known as black light, has the longest wavelength, ranging between 315nm to 400nm.

- UV-B – known as the medium wavelength, ranges between 280nm and 315nm.

- UV-C – the shortest wavelength, ranges between 200nm and 280nm.

UV-C is germicidal, meaning it can be used effectively as a disinfectant to kill microorganisms, such as bacteria and viruses.

When the DNA of microorganisms absorbs UV light, it stops them from being able to reproduce and duplicate, thereby preventing their growth.

What is a UV-C LED?

Light-emitting diodes (LEDs) are semiconductor devices that are made up of multiple layers of substrate materials. They can be designed so that a wavelength can be inputted and emit photons in the UV-C range that can be used to stop the replication of bacteria.

UV-C LEDs perform the same functions of conventional mercury-vapor lamps but have many benefits in comparison.

- Environmentally Friendly – conventional UV lamps use mercury that is difficult to handle and costs a great deal to dispose of safely.

- Small Design Footprint – LEDs are much more compact compared to their mercury-vapor counterpart, meaning they can be integrated easily into new innovative designs.

- Instant On/Off – UV-C LEDs work instantly, so there is no need for a warm-up time that is a common constraint of mercury-vapor lamps.

- Unlimited Cycling – On/Off cycles do not impact the life of the LEDs, meaning there is an unlimited scope for lamp cycling.

- Temperature Independent – LEDs can emit photons from a different surface as their heat emissions. They can be designed so that if UV-C LEDs are being used in water purification, they will not transfer heat into the water.

- Wavelength Selection – One of the greatest benefits of UV-C LEDs is that users can configure them to choose a specific wavelength that is best suited for maximum absorption of light for the chosen microorganism.

How Does UV-C LED Disinfection Work?

Different types of UV-C disinfection can work depending on the scale of the solution being implemented. However, the principles of how UV-C disinfection works remain the same.

An LED produces a pre-selected wavelength from a small amount of electricity. The LED then emits UV-C photons that penetrate the cells and damage the nucleic acid in the microorganism DNA.

As these cells cannot replicate, it renders the harmful microorganism inactive. As a result, UV-C LEDs allow for high-intensity radiation to kill the bacteria in seconds, and its effectiveness is measured in LOGs.

UV LED Disinfection Technology

Ultraviolet disinfection technology has been the star performer in water and air treatment over the past two decades, due in part to its ability to provide treatment without the use of harmful chemicals.

UV represents wavelengths that fall between visible light and x-ray on the electromagnetic spectrum. The UV range can be further divided into UV-A, UV-B, UV-C, and Vacuum-UV. The UV-C portion represents wavelengths from 200 nm – 280 nm, the wavelength used in our LED disinfection products.

UV-C photons penetrate cells and damage the nucleic acid, rendering them incapable of reproduction, or microbiologically inactive. This process occurs in nature; the sun emits UV rays that perform this way.

UV Disinfection Process

At AquiSense, we use Light Emitting Diodes to generate high levels of UV-C photons.

The rays are directed at viruses, bacteria and other pathogens within water and air,

or on surfaces to render those pathogens harmless in seconds.

Applications of UV-C LEDs

There are many applications where UV-C LEDs are being tested to see if they can become a solution to not just current disinfection challenges but our future ones too.

Drinking water disinfection, water purification, and treatment is an optimal solution that is chemical-free, has no risk of creating harmful by-products, is an effective pathogen inactivation, and is very low maintenance.

As well as water, UV-C LEDs are offering disinfection for both air and surfaces. UV-C LED air purifiers for HAVC (heating, ventilation, and air conditioning) are being used increasingly in the commercial landscape.

AquiSense offers a full spectrum of applications, including residential, commercial, healthcare, pharmaceutical, transport, life sciences, defense, and emergency response.

| Market Segment | Example Applications | UV-C LED system benefits: Top 3 important attributes valued by segment |

|---|---|---|

| Residential | POE, Appliances, Faucets | Ultra-compact footprint, Plug and play (e.g. easy to retrofit), Low power draw |

| Commercial | Food and beverage service, Water dispensers and fountains | Ultra-compact footprint, Low power draw, No heating of water |

| Healthcare | HAI control, Dialysis, Dental | Mercury-free, Chemical-free, Durable (e.g. vibration resistance) |

| Transportation | RV and boating, Automotive, Aviation, Space | Chemical-free, Durable, Lightweight |

| Life Sciences | Bio-pharma, Ultrapure water | Point-of-use distribution, Mercury-free, Chemical-free |

| Defense/Emergency Response | Personal hydration, Remote treatment | Ultra-compact footprint, Lightweight, Durable (e.g. vibration resistance) |

UV LED Benefits

UV-C LED Technology - The Next Revolution

In much the same way that LEDs have revolutionized the display and lighting industries, UV-C LED technology is providing new, improved, and expanded solutions in air, surface, and water treatment. Dual barrier, post-filtration protection is now available where mercury-based systems could not previously have been conceivably used.

| Attribute | Conventional Mercury Lamp | UV-C LED | Product Implication |

|---|---|---|---|

| Mercury Content | 5-200 mg | None | Safe disposal – no special handling |

| Lifetime | 5,000 – 15,000 hours | 10,000 hours | Flexible operation |

| On/Off Cycles | Max. 4 per day | Unlimited | Intermittent-flow friendly |

| Warm-up Time | Up-to 15 minutes | Instantaneous | Extended replacement intervals |

| Operating Surface Temp. | 100-600° C | Same as process water | Zero-flow friendly does not promote fouling |

| Architecture | Cylindrical tube | Point source | Versatile implementation |

| Durability | Fragile glass tube | Rugged semiconductor | Versatile operation |

| Wavelength | Polychromatic (200-300nm) Monochromatic (254 nm) | Selectable (250-300nm) | No wasted energy & targeted performance |

| Power Supply | 110-240V ACv | 6-30V DC | Battery/Solar option |

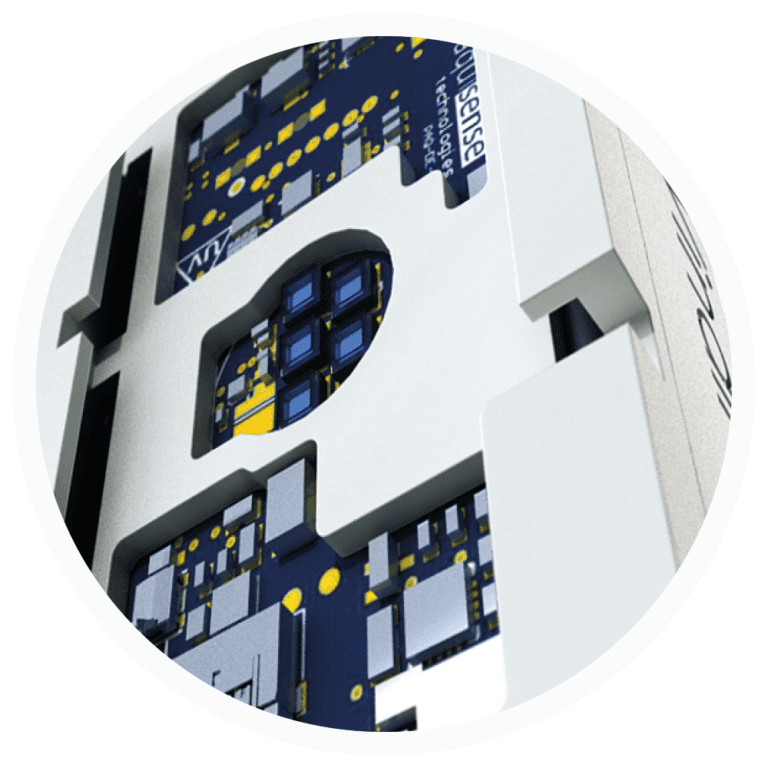

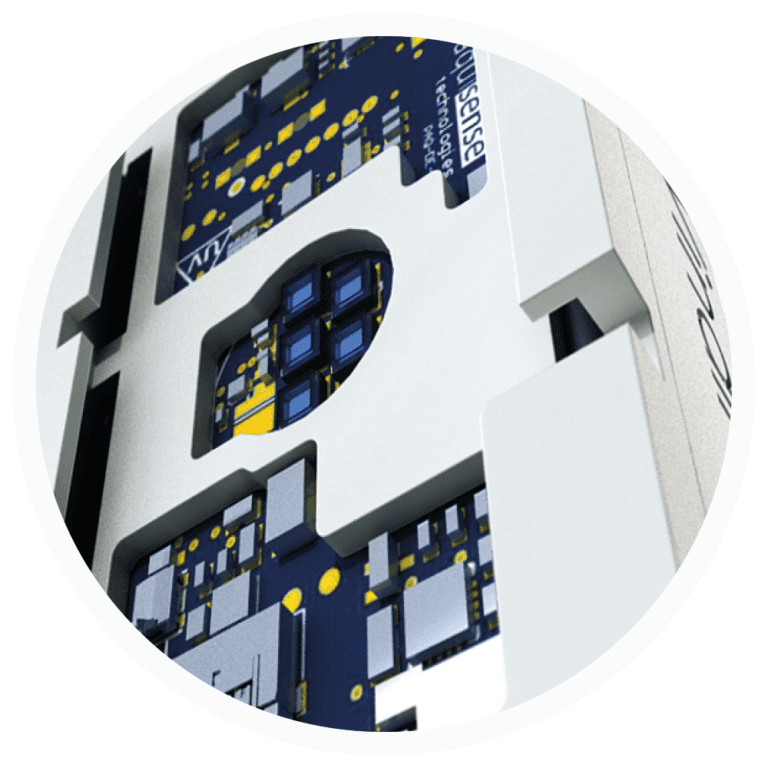

LEDs produce a selected wavelength from a small amount electricity. Depending on the composition of the LED it can produce anywhere from infrared, visible, and now UV-C wavelengths.

The side view of the LED shows that as power passes through the LED layers, it activates the desired wavelength.

The LED is then packaged to allow for electrical connection, thermal management, and physical protection. This helps maintain efficiency for the LED output and lamp life.

These LEDs can be integrated into various systems to treat water, air, and surfaces. These systems also work with the LED packaging to disperse heat and improve efficiency of the disinfection process.

Back of lamp module

with LEDs integrated

Front of replaceable module

with thermal management options

Types of UV-C LED Disinfection Systems

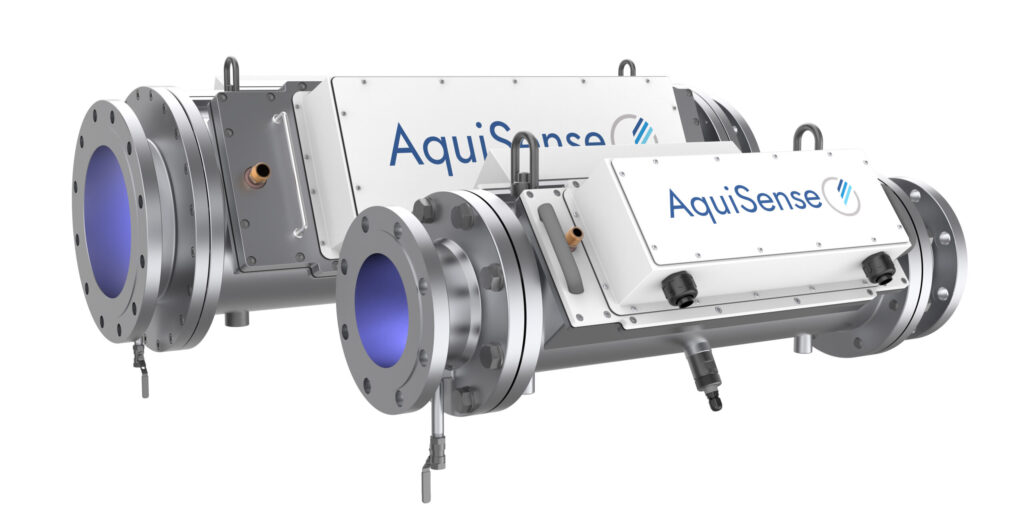

UV-C LED technology is used for water dispensing and water-cooling applications as well as residential, commercial, industrial and municipal applications.

Disinfection system concepts for integrating UV-C LED systems.

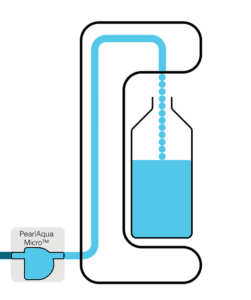

Inlet Disinfection System

For pre-existing water systems, the disinfection process is often left outside of the device, which can leave an opening for bacteria to grow at any point in the system. In the inlet model, the UV-C LED is easy to replace and will last considerably longer than its mercury-vapor counterpart.

While there is no need to redesign existing systems, the trade-off of having an inlet system is that the components are visible and are therefore more susceptible to damage.

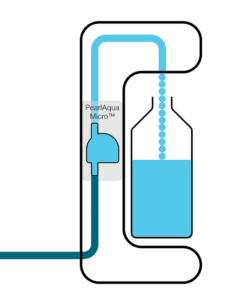

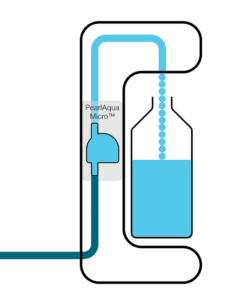

In Process Disinfection

In this configuration, UV-C LEDs are integrated into the current system. This set up has several benefits: the UV-C LED component is protected, the amount of contamination between unit and dispenser is significantly reduced, and this model makes use of the compact nature of the LEDs.

The one major drawback to the in-process disinfection model is that it is susceptible to retrograde contamination and bacteria growth up the pipeline.

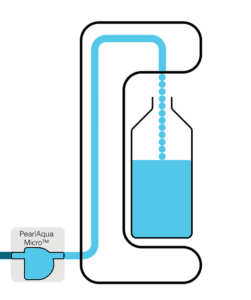

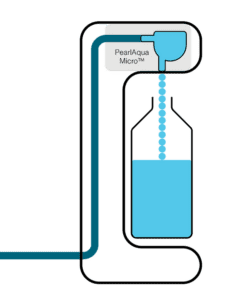

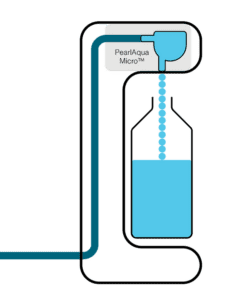

Point of Use Disinfection

This system offers the greatest amount of protection by taking advantage of the full attributes of UV-C LED technology. Installed at the point of consumption, the system features an instant on/off switch.

Point of Use disinfectant systems have the most benefits, but due to the complexity and expense of the new system, they are the most complicated to install and design.

They can become contaminated by an external source, in which the bacteria can grow through the pipe into the system. This can be prevented by the regular cycling of the system.

Disinfection of Drinking Water

UV-C LEDs are successful in the disinfection of drinking water.

UV-C LEDs are being used to disinfect drinking water at various points in the treatment cycle, from source to consumption. It can take a few seconds for the water to become clean in a UV-C model, and the new technology allows for LEDs to be placed at a different point to ensure decontamination.

It works initially when a water reservoir is exposed to a number of high-powered LEDs that disinfect the water. They emit powerful UV-C photons in the range of 200 – 280nm that pass through the water, stopping the bacteria in the water from being able to reproduce.

Many newer systems have taken advantage of the compact size of the LEDs and can disinfect at the end stage of the drinking water journey – ensuring complete disinfection.

What is LOG reduction?

LOG reduction is used to measure how thoroughly a decontamination process reduces the amount of contamination.

For example, 1-log reduction means the number of bacteria is 10 times smaller, 2-log equals 100 times smaller, 3-log equals 1,000, and so on.

To put this into perspective, if a surface had 100,000 microbes present, it would take 5-log reduction to bring the number of microorganisms down to just one.

Water Treatment and Pathogen Control

A paper released in Science of the Total Environment journal looked at various microbial disinfection methods for UV-LED water treatment systems. It found that UV-C LEDs were effective in the inactivation efficiency and energy consumption of UV-LEDs for pathogens at various wavelengths.

As UV-C LEDs can select various wavelengths to target specific microorganism present in infected water and deactivate them, different pathogens and bacteria stop replicating when they have been exposed to different wavelengths.

UV LED Benefits: Mercury-free

Although UV disinfection is generally considered safer than chemical disinfection, all conventional UV lamps typically use between 5-200 mg of mercury per lamp.

These mercury lamps require routine replacement and are susceptible to breakage during transportation, handling, and operation. UV LEDs are mercury-free and provide a safer alternative. This has created new markets for UV disinfection where traditional UV lamps containing mercury were banned for safety reasons (e.g. medical devices, space).

Conventional UV lamps hold their mercury either in a liquid form (more common in medium pressure lamps) or an amalgam (more common in low pressure, high output lamps). Amalgam UV lamps contain solid “spots” which consist of an alloy of mercury and another element, such as indium or gallium. Liquid mercury lamps have the potential to be hazardous both during operation and when the lamp is off. While the lamp is operating the mercury vaporizes; if the lamp is broken, mercury vapor is easily dissolved into the treated product. Accidents and improper procedures increase the risk of exposure to people and the environment.

The inherent stable crystal structure of an LED ensures that UV-C LEDs are very robust to mechanical or environmental shock.

UV-C LEDs do contain small amounts of elements such as the metals gallium and magnesium and the metalloids silicon and boron (although boron is not predominantly used). These metals and or metalloids are bound within a stable crystal structure and cannot leach into the environment.

Minamata Convention

The Minamata Convention on Mercury was initiated by the United Nations Environmental Programme (UNEP) to protect human health and the environment from anthropogenic emissions and releases of mercury. The UNEP has set the goal for mercury to be phased out of production by the year 2050.

Although the Minamata Convention does not specifically prohibit the manufacture and sale of UV mercury-vapor lamps, it will provide a generally positive influence for the more widespread adoption of alternative technologies. Potential responses may include the following actions:

- Corporations that use UV systems in products or manufacturing processes (e.g. white goods, beverage, microelectronics, life sciences) may implement best practices by selecting an LED option by the influence of the Minamata Convention, not by enforcement.

- Original Equipment Manufacturers that currently employ conventional mercury lamps may see a conflict with the use of mercury-based products to their own environmental policies and, based on Minamata regulations, might start a transition to develop new products using mercury-free light sources.

- Municipalities may also follow suit in adopting UV-C LEDs, although it is more likely that they will require more time to adopt the new technology.

- There will always be a percentage of people that will look for “eco-friendly” product options. As the Minamata Convention raises awareness of the effects of mercury, it inherently affects the use of mercury-based lamps without banning the sale or manufacturing of these lamps.

- Regulators will likely have a slow transition from mercury to UV-C LED lamps. Regulators will always look for viable alternatives to mercury, as it is their mandate to steer technology to the most holistically sound solution.

- https://materion.com/resource-center/newsletters/materials-news-stats-and-chats/killing-germs-with-leds

- http://wcponline.com/2018/05/15/smartphones-water-disinfection-micro-uv-c-led-systems/

- https://dacemirror.sci-hub.tw/journal-article/dbcdbbb924a6151ce7bfa7b417eb4c16/li2018.pdf?fbclid=IwAR2-Go0_cK0P7qy-pTec8vAvgHN3Et4SGi2CgOMYOWPRskTJ24W8aXer9ck

- https://www.aquisense.com/uv-leds-and-space-exploration

- https://www.aquisense.com/technology

- https://ciriscience.org/ieq-measurement/what-is-log-reduction/

- https://www.waterworld.com/residential-commercial/article/14308783/where-to-install-uv-c-led-systems?page=1&filters=%7B%22%3A%22aquisense%22%2C%22page%22%3A1%2C%22status%22%3A%5B%221%22%5D%2C%%22impliedSchedules%22%3Atrue%7D&sort=published

- https://www.sciencedirect.com/science/article/pii/S2589914724000264

- https://uvsolutionsmag.com/article/2023/las-vegas-valley-treats-drinking-water-with-uvc-led-technology/