AquiSense

Where to install UV-C LEDs

Ultraviolet LEDs are gaining interest in water dispensing applications, to provide enhanced disinfection. While this digital technology boasts several unique benefits (i.e. instant on, small footprint, long replacement intervals), exploiting these attributes takes expertise, experience and engineering know-how.

AquiSense Technologies offers added insight as we have been designing for these solutions for years. Below are a few installation concepts to keep in mind when designing for the integration of the world’s smallest UV disinfection system, the PearlAqua Micro™.

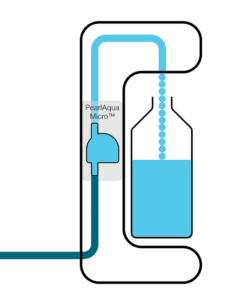

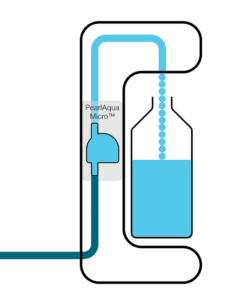

Inlet Disinfection System

For pre-existing water systems, the disinfection process is often left outside of the device, which can leave an opening for bacteria to grow at any point in the system. In the inlet model, the UV-C LED is easy to replace and will last considerably longer than its mercury-vapor counterpart.

While there is no need to redesign existing systems, the trade-off of having an inlet system is that the components are visible and are therefore more susceptible to damage.

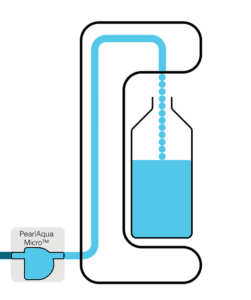

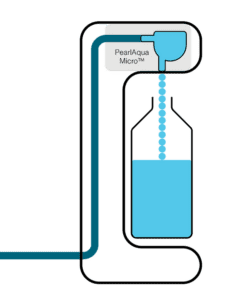

In Process Disinfection

In this configuration, UV-C LEDs are integrated into the current system. This set up has several benefits: the UV-C LED component is protected, the amount of contamination between unit and dispenser is significantly reduced, and this model makes use of the compact nature of the LEDs.

The one major drawback to the in-process disinfection model is that it is susceptible to retrograde contamination and bacteria growth up the pipeline.

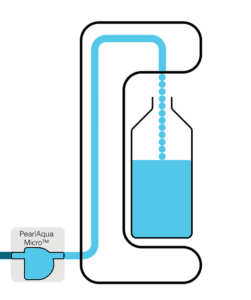

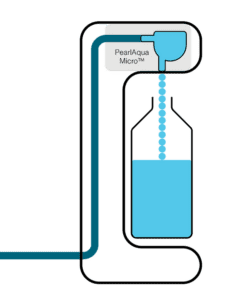

Point of Consumption Disinfection

This system offers the greatest amount of protection by taking advantage of the full attributes of UV-C LED technology. Installed at the point of consumption, the system features an instant on/off switch.

Point of Consumption disinfectant systems have the most benefits, but due to the complexity and expense of the new system, they are the most complicated to install and design.

They can become contaminated by an external source, in which the bacteria can grow through the pipe into the system. This can be prevented by the regular cycling of the system.

Each application has different needs and reasons for disinfection. Any of these options are suitable depending on the internal space available, the need for replacement, and the level of disinfection. The PearlAqua Micro provides flexible options for any need.